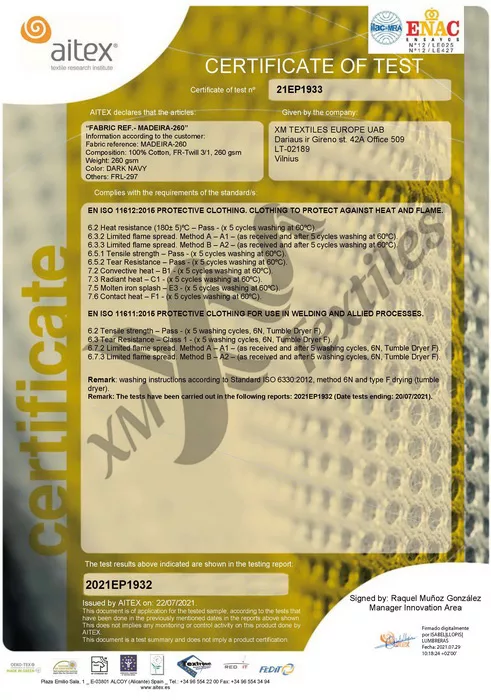

Alicante, ES – JULY 22, 2021 – XM FireLine announced today its Madeira-260 flame retardant fabric has been certified by the Aitex (Spain) to EN 11611 and EN 11612 safety standards.

Madeira-260 is a pure cotton flame-retardant protective fabric made of a long-staple pure cotton. This fabric can be used for everyday flame-retardant workwear such as FR-pants, FR-jackets, FR-bibs, and FR-overalls.

EN 11611 and EN 11612 certification involved tests for Heat resistance, Limited flame spread, Tensile strength, Tear Resistance, Convective, Contact and Radiant heat, Molten iron splash, Domestic washing 5 cycles at 60C.

Now we can say Madeira-260 has reached high level of durability and performance to PASS the certification and go to the clients.

FR fabric Madeira-260 is designed to bring new level of comfort for all the wearers of FR-clothing. We do hope our clients appreciate its style and comfort. More information about the fabric you can find on product page.