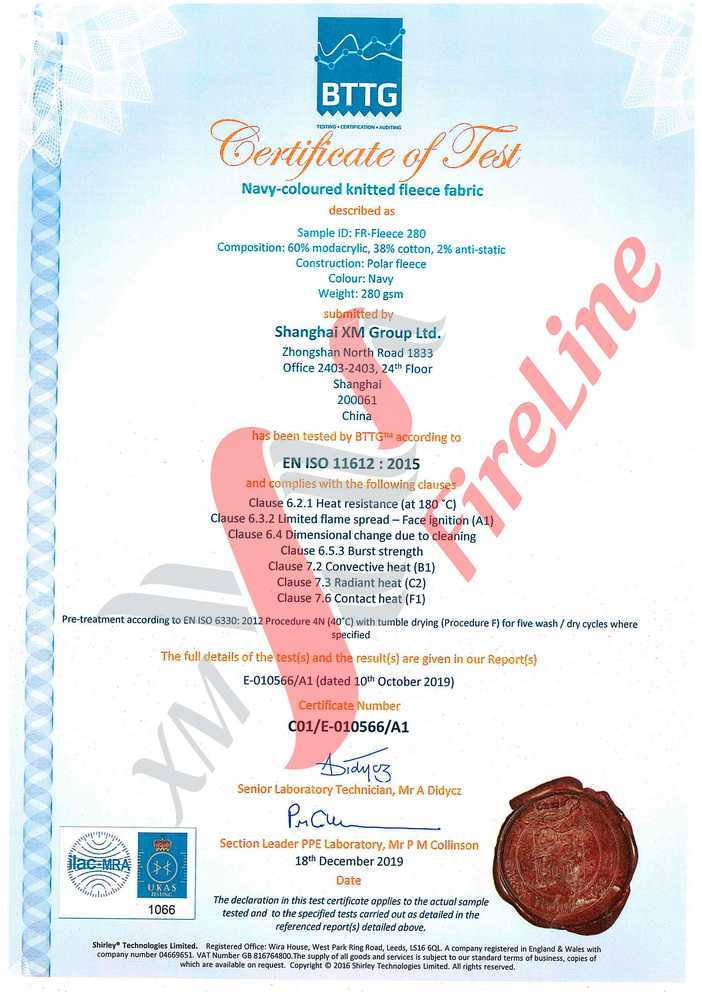

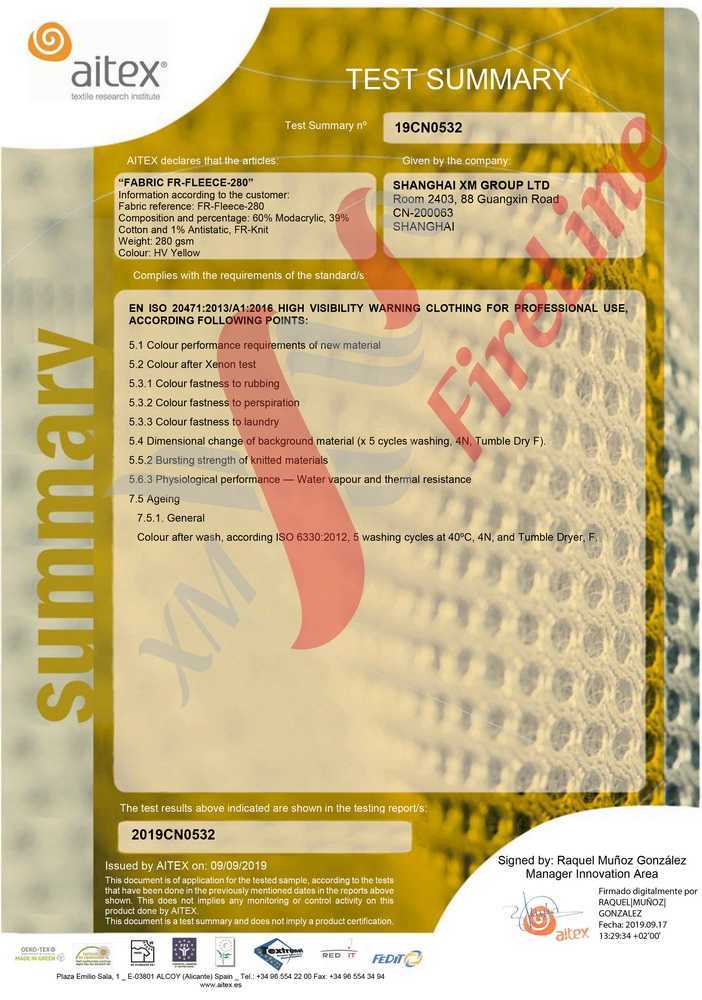

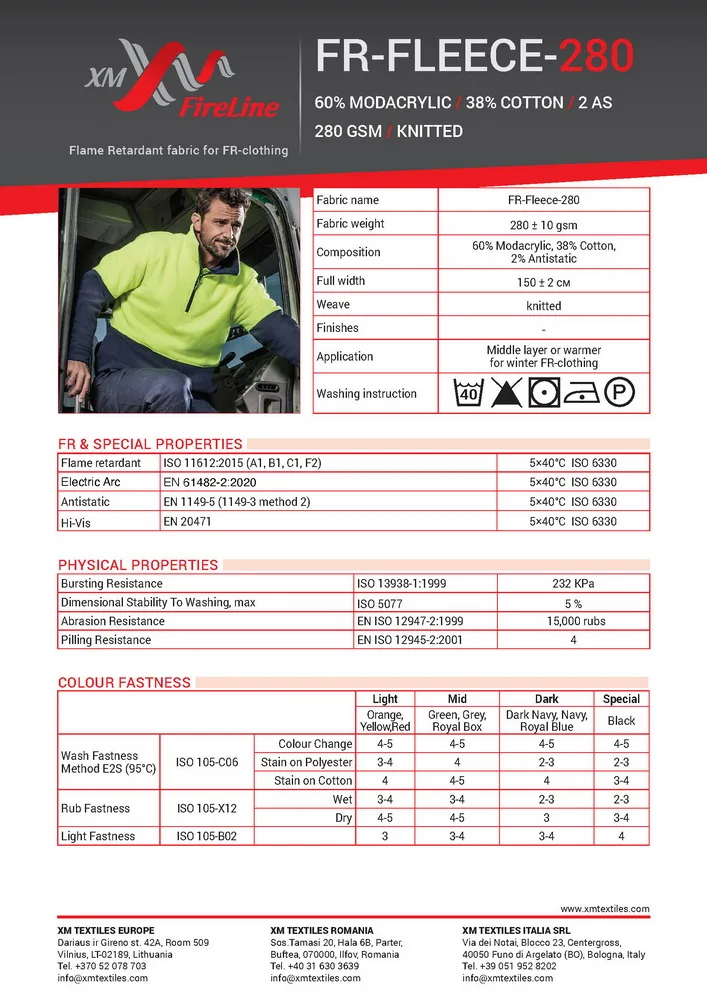

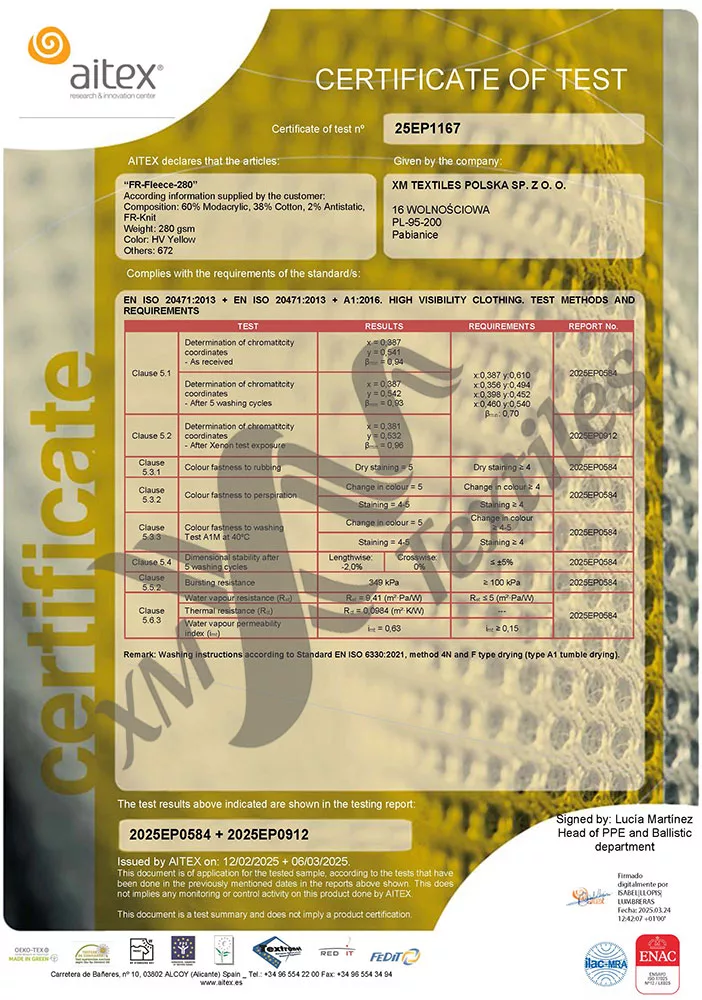

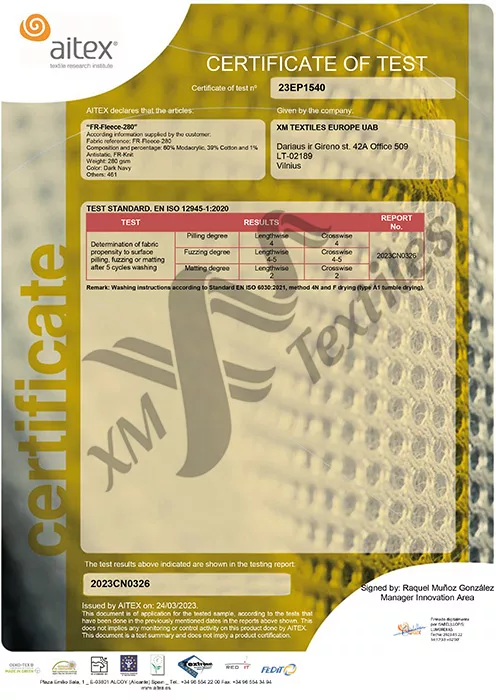

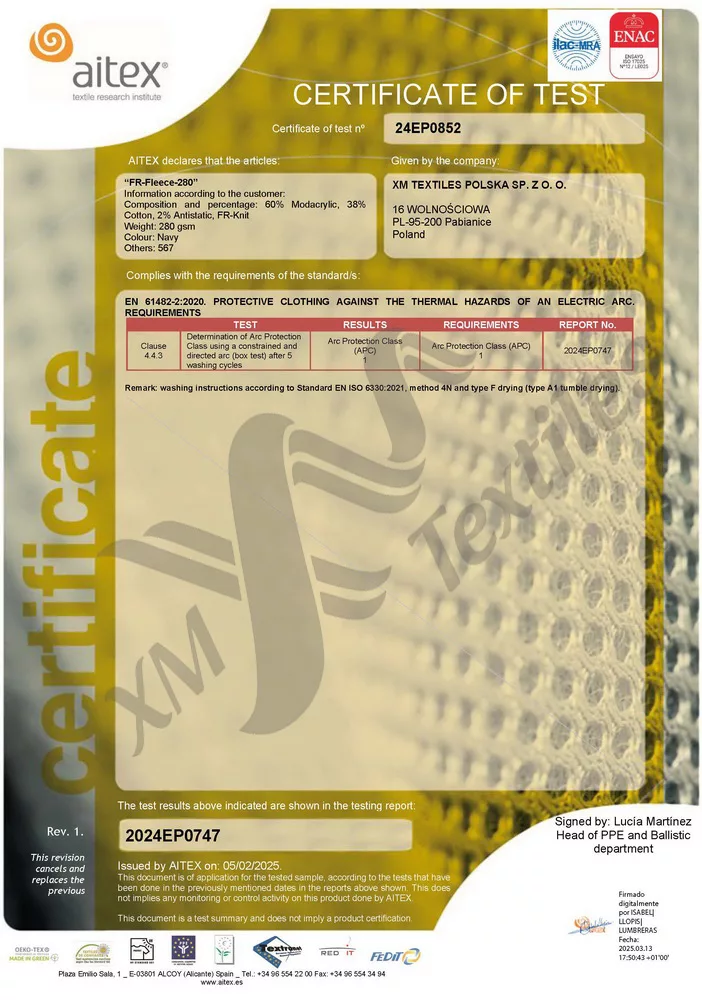

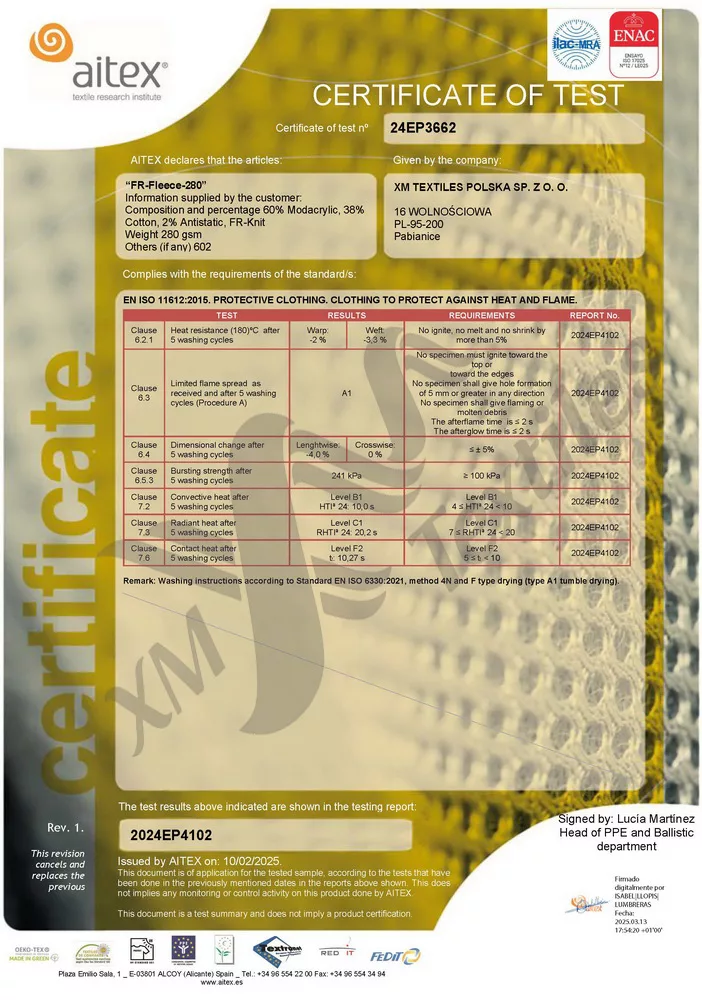

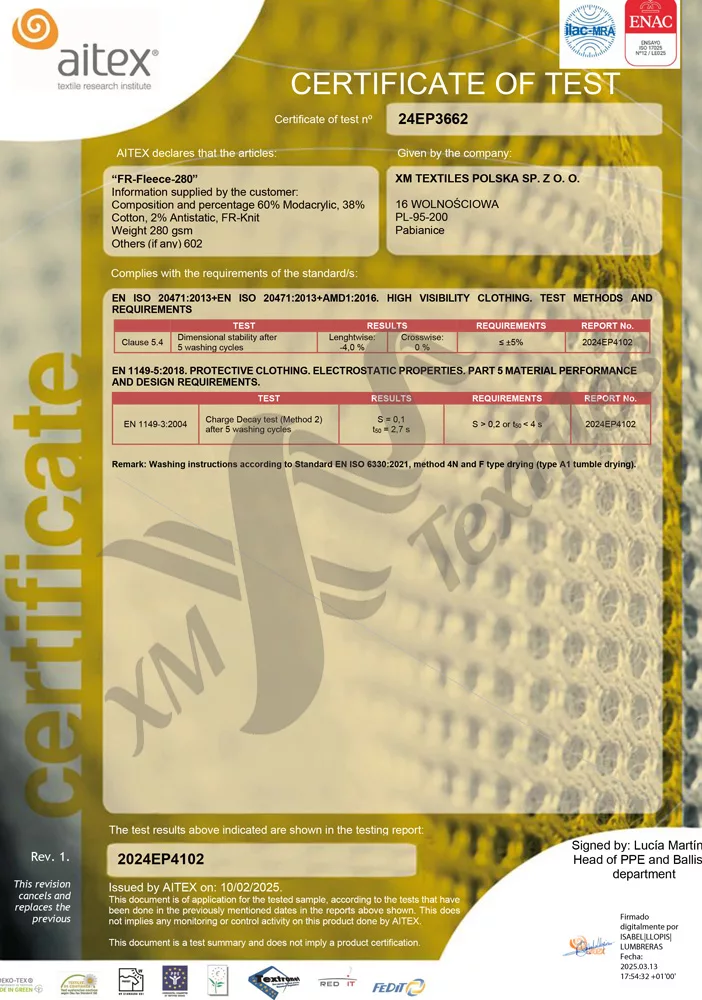

FR-Fleece-280

280gsm | 60% Modacrylic, 38% Cotton, 2% AS | Knit fabric

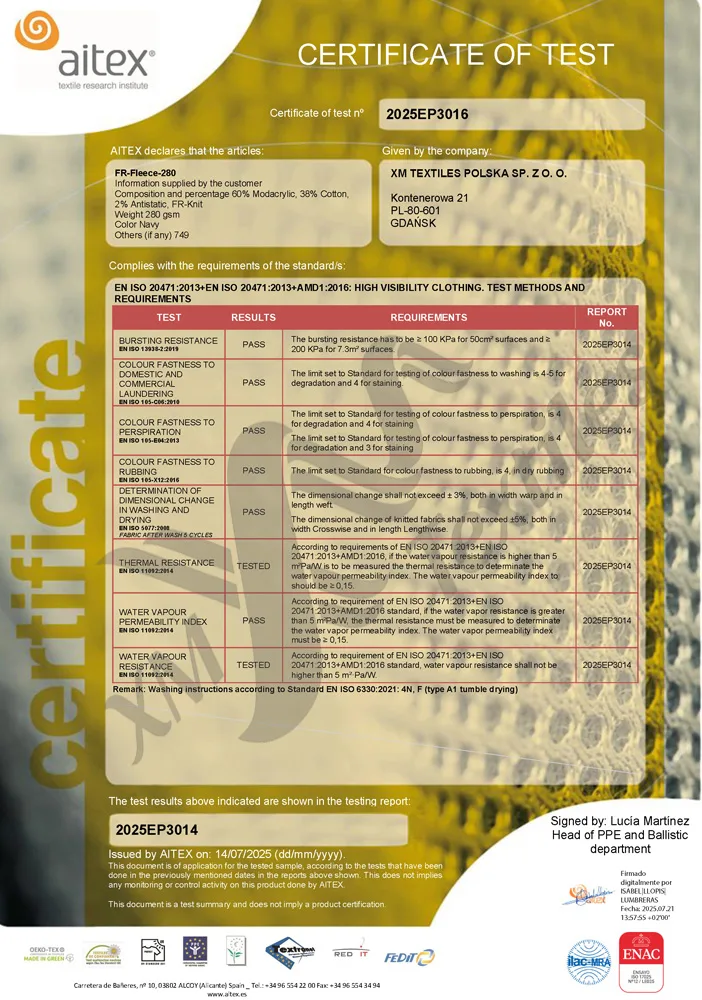

(3 Certificates)

Flame Retardant fabric

FR-Fleece is a 280gsm knitted fabric with antistatic and flame retardant properties. FR-Fleece is designed to take the softness and warmth of fleece fabric and add some extra features such as heat and flame resistance.

Show more

Show less

Key features: Flame Retardant, Antistatic

Certifications: ISO 11612, EN 1149-3, EN 1149-5, EN 20471, Oeko-tex

Related Products

-

270 gsm | 58% Modacrylic, 30% Cotton, 5% Para-Aramid, 5% XLANCE®, 2% AS | Rip-stop

(0 Certificates)

Flame Retardant fabric

CAPRI-270 combines inherent flame resistance with rip-stop durability – two layers of protection that won’t fail when you need them most.The 58% modacrylic composition means FR protection is built into every fiber, not applied as a treatment. It doesn’t wash out, doesn’t wear off, doesn’t degrade. The rip-stop weave stops tears before they start, extending garment life in environments where snags and abrasion are daily reality.

Ideal Applications:

- Oil & gas industry workwear

- Petrochemical facility uniforms

- Utilities and energy sector clothing

- Emergency services station wear

- Industrial maintenance workwear

- Transportation and logistics safety apparel

- Construction site protective garments

- Arc flash protection clothing

Technical Advantages: The modacrylic-rich composition provides inherent flame resistance that remains effective throughout the garment’s lifecycle. The cotton component ensures breathability during physically demanding work, while the rip-stop construction significantly reduces fabric damage from snags and tears. The antistatic fiber integration adds essential safety for work in potentially explosive atmospheres.Key features: Flame Retardant, Antistatic

Certifications: EN 1149, EN 11611, EN 11612, EN 61482-2, Oeko-tex 100

Flame Resistant Inherent fabricsCAPRI-270

270 gsm | 58% Modacrylic, 30% Cotton, 5% Para-Aramid, 5% XLANCE®, 2% AS | Rip-stop

(0 Certificates)

Flame Retardant fabric

CAPRI-270 combines inherent flame resistance with rip-stop durability – two layers of protection that won’t fail when you need them most.The 58% modacrylic composition means FR protection is built into every fiber, not applied as a treatment. It doesn’t wash out, doesn’t wear off, doesn’t degrade. The rip-stop weave stops tears before they start, extending garment life in environments where snags and abrasion are daily reality.

Ideal Applications:

- Oil & gas industry workwear

- Petrochemical facility uniforms

- Utilities and energy sector clothing

- Emergency services station wear

- Industrial maintenance workwear

- Transportation and logistics safety apparel

- Construction site protective garments

- Arc flash protection clothing

Technical Advantages: The modacrylic-rich composition provides inherent flame resistance that remains effective throughout the garment’s lifecycle. The cotton component ensures breathability during physically demanding work, while the rip-stop construction significantly reduces fabric damage from snags and tears. The antistatic fiber integration adds essential safety for work in potentially explosive atmospheres.Key features: Flame Retardant, Antistatic

Certifications: EN 1149, EN 11611, EN 11612, EN 61482-2, Oeko-tex 100

-

260gsm | 55% Modacrilic, 44% Cotton, 1% AS | Rip-stop

(4 Certificates)

Flame Retardant fabric

DEVON-260 combines inherent flame resistance with rip-stop durability – two layers of protection that won’t fail when you need them most.The 55% modacrylic composition means FR protection is built into every fiber, not applied as a treatment. It doesn’t wash out, doesn’t wear off, doesn’t degrade. The rip-stop weave stops tears before they start, extending garment life in environments where snags and abrasion are daily reality.

Ideal Applications:

- Oil & gas industry workwear

- Petrochemical facility uniforms

- Utilities and energy sector clothing

- Emergency services station wear

- Industrial maintenance workwear

- Transportation and logistics safety apparel

- Construction site protective garments

- Arc flash protection clothing

Technical Advantages: The modacrylic-rich composition provides inherent flame resistance that remains effective throughout the garment’s lifecycle. The cotton component ensures breathability during physically demanding work, while the rip-stop construction significantly reduces fabric damage from snags and tears. The antistatic fiber integration adds essential safety for work in potentially explosive atmospheres.Key features: Flame Retardant, Antistatic

Certifications: EN 1149, EN 11611, EN 11612, EN 61482-2, Oeko-tex 100

Flame Resistant Inherent fabricsDEVON-260

260gsm | 55% Modacrilic, 44% Cotton, 1% AS | Rip-stop

(4 Certificates)

Flame Retardant fabric

DEVON-260 combines inherent flame resistance with rip-stop durability – two layers of protection that won’t fail when you need them most.The 55% modacrylic composition means FR protection is built into every fiber, not applied as a treatment. It doesn’t wash out, doesn’t wear off, doesn’t degrade. The rip-stop weave stops tears before they start, extending garment life in environments where snags and abrasion are daily reality.

Ideal Applications:

- Oil & gas industry workwear

- Petrochemical facility uniforms

- Utilities and energy sector clothing

- Emergency services station wear

- Industrial maintenance workwear

- Transportation and logistics safety apparel

- Construction site protective garments

- Arc flash protection clothing

Technical Advantages: The modacrylic-rich composition provides inherent flame resistance that remains effective throughout the garment’s lifecycle. The cotton component ensures breathability during physically demanding work, while the rip-stop construction significantly reduces fabric damage from snags and tears. The antistatic fiber integration adds essential safety for work in potentially explosive atmospheres.Key features: Flame Retardant, Antistatic

Certifications: EN 1149, EN 11611, EN 11612, EN 61482-2, Oeko-tex 100

-

310 gsm | 42% Modacrylic, 29% Cotton, 19% FR PA, 5% Para-Aramid, 4% EOL, 1% AS | Twill 2/1

(0 Certificates)

Flame Retardant fabric

The first inherent FR softshell fabric with integrated high-visibility protection. FR SOFTSHELL-310 delivers weather resistance, breathability, and permanent flame protection in one fabric – eliminating the need to layer non-FR outerwear over FR base garments.

Unlike standard softshell fabrics, the 42% modacrylic composition means FR protection that won’t wash out. The 19% FR Polyamide adds weather resistance and durability, while P-Aramid reinforcement provides mechanical strength where it counts. The 4% elastomeric component allows natural movement during demanding outdoor work. High-visibility yellow ensures workers stay visible in low-light conditions and adverse weather.

For operations where workers need flame protection, weather resistance, and visibility – all in one garment.

Ideal Applications:

- Emergency services outerwear

- High-visibility FR jackets and vests

- Utilities and energy sector weather protection

- Transportation and logistics safety apparel

- Construction site protective outerwear

- Industrial maintenance FR jackets

- Manufacturing facility safety wear

- Corporate FR programs requiring visibility

Key Advantages:

- All-weather protection: Water-resistant finish (EN 343) keeps workers dry without compromising breathability

- High visibility: HV Yellow meets EN 20471 standards for enhanced worker visibility

- Permanent FR: Inherent flame resistance from modacrylic fibers – certified through 50 industrial washes at 60°C

- Multi-risk certified: Protects against heat, flame, arc flash, and electrostatic discharge

- Eliminates layering problems: Single-layer solution replaces FR base + non-FR weather shell combinations

- Built for durability: FR Polyamide and P-Aramid reinforcement extend garment lifespan in demanding conditions

Key features: Flame Retardant, Antistatic

Certifications: EN 3434, EN 20471, Oeko-tex 100

Flame Resistant Inherent fabricsFR SOFTSHELL-310

310 gsm | 42% Modacrylic, 29% Cotton, 19% FR PA, 5% Para-Aramid, 4% EOL, 1% AS | Twill 2/1

(0 Certificates)

Flame Retardant fabric

The first inherent FR softshell fabric with integrated high-visibility protection. FR SOFTSHELL-310 delivers weather resistance, breathability, and permanent flame protection in one fabric – eliminating the need to layer non-FR outerwear over FR base garments.

Unlike standard softshell fabrics, the 42% modacrylic composition means FR protection that won’t wash out. The 19% FR Polyamide adds weather resistance and durability, while P-Aramid reinforcement provides mechanical strength where it counts. The 4% elastomeric component allows natural movement during demanding outdoor work. High-visibility yellow ensures workers stay visible in low-light conditions and adverse weather.

For operations where workers need flame protection, weather resistance, and visibility – all in one garment.

Ideal Applications:

- Emergency services outerwear

- High-visibility FR jackets and vests

- Utilities and energy sector weather protection

- Transportation and logistics safety apparel

- Construction site protective outerwear

- Industrial maintenance FR jackets

- Manufacturing facility safety wear

- Corporate FR programs requiring visibility

Key Advantages:

- All-weather protection: Water-resistant finish (EN 343) keeps workers dry without compromising breathability

- High visibility: HV Yellow meets EN 20471 standards for enhanced worker visibility

- Permanent FR: Inherent flame resistance from modacrylic fibers – certified through 50 industrial washes at 60°C

- Multi-risk certified: Protects against heat, flame, arc flash, and electrostatic discharge

- Eliminates layering problems: Single-layer solution replaces FR base + non-FR weather shell combinations

- Built for durability: FR Polyamide and P-Aramid reinforcement extend garment lifespan in demanding conditions

Key features: Flame Retardant, Antistatic

Certifications: EN 3434, EN 20471, Oeko-tex 100