FR fabrics

-

480gsm | 100% Cotton | Satin 5/2

(2 Certificates)

Flame Retardant fabric

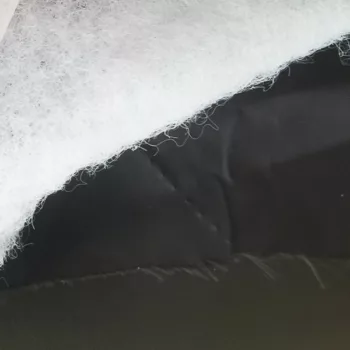

Gefest-480 is a heavyweight 480gsm pure cotton protective fabric with a flame retardant finish. Smooth satin 5/2 weave. Gefest is a flame retardant fabric specifically designed for welders working in extreme conditions on offshore oil platforms, in dry docks and in naval shipyards.[show_more more="Show more" less="Show less" color="#629e11" align="left"]Gefest is an extremely durable fabric due to its innovative composition of long staple cotton fibres twisted in warp and weft. The fabric is so strong that it’s impossible to tear with your hands. Gefest-480 flame retardant protective fabric is intended for professional welders’ clothing in various fields such as mechanical engineering, metallurgy, oil and gas pipeline construction, automotive, etc. The satin weave of Gefest-480 is extremely useful in welders’ overalls, bibs or aprons as it allows molten metal droplets to easily run off the smooth surface of the fabric. Made from natural fibres, it is very soft and comfortable to wear and at the same time protects against the risks of flash fire and electric arc.[/show_more]

Key features: Industrial wash, Flame Retardant, 100×750C (limited flame spread), EN 11612 D2 (5×750C)

Certifications: ISO 11611, ISO 11612, ISO 15797, Oeko-tex 100

Flame Retardant Cotton FabricsGEFEST-480

480gsm | 100% Cotton | Satin 5/2

(2 Certificates)

Flame Retardant fabric

Gefest-480 is a heavyweight 480gsm pure cotton protective fabric with a flame retardant finish. Smooth satin 5/2 weave. Gefest is a flame retardant fabric specifically designed for welders working in extreme conditions on offshore oil platforms, in dry docks and in naval shipyards.[show_more more="Show more" less="Show less" color="#629e11" align="left"]Gefest is an extremely durable fabric due to its innovative composition of long staple cotton fibres twisted in warp and weft. The fabric is so strong that it’s impossible to tear with your hands. Gefest-480 flame retardant protective fabric is intended for professional welders’ clothing in various fields such as mechanical engineering, metallurgy, oil and gas pipeline construction, automotive, etc. The satin weave of Gefest-480 is extremely useful in welders’ overalls, bibs or aprons as it allows molten metal droplets to easily run off the smooth surface of the fabric. Made from natural fibres, it is very soft and comfortable to wear and at the same time protects against the risks of flash fire and electric arc.[/show_more]

Key features: Industrial wash, Flame Retardant, 100×750C (limited flame spread), EN 11612 D2 (5×750C)

Certifications: ISO 11611, ISO 11612, ISO 15797, Oeko-tex 100

-

Spark + FR-Wadding (Ovata) | Plain 1/1

Q6 Spark 170gsm + 120gsm Wadding (Ovata)

Q6 Spark 170gsm + 150gsm Wadding (Ovata)(0 Certificates)

Flame Retardant fabric

This specialized flame-retardant quilted fabric addresses the critical dual needs of thermal protection and fire safety in high-risk work environments. Certified to EN 11611, EN 531, and EN 470-1 standards, it protects workers from both cold temperatures and flame hazards—a crucial combination for industries such as welding, metal processing, and petrochemical work. The 150g 100% polyester construction provides reliable warmth without compromising on safety, making it essential for compliant protective workwear in hazardous cold environments.

Key features: Flame Retardant, Thermal insulation

Certifications: Oeko-tex 100

Flame Retardant Polyester FabricsQ6. Quilted FR-fabric (Ovata) 1-Sided

Spark + FR-Wadding (Ovata) | Plain 1/1

Q6 Spark 170gsm + 120gsm Wadding (Ovata)

Q6 Spark 170gsm + 150gsm Wadding (Ovata)(0 Certificates)

Flame Retardant fabric

This specialized flame-retardant quilted fabric addresses the critical dual needs of thermal protection and fire safety in high-risk work environments. Certified to EN 11611, EN 531, and EN 470-1 standards, it protects workers from both cold temperatures and flame hazards—a crucial combination for industries such as welding, metal processing, and petrochemical work. The 150g 100% polyester construction provides reliable warmth without compromising on safety, making it essential for compliant protective workwear in hazardous cold environments.

Key features: Flame Retardant, Thermal insulation

Certifications: Oeko-tex 100

-

Spark + FR-Wadding (Ovata) | Plain 1/1

Q7 Spark 170gsm + 120gsm Ovata + Spark 170gsm

Q7 Spark 170gsm + 150gsm Ovata + Spark 170gsm(0 Certificates)

Flame Retardant fabric

The most comprehensive thermal and safety solution, this quilted fabric features 100% flame-retardant polyester with an additional FR lining to create multiple protective barriers. Certified to EN 11611, EN 531, and EN 470-1 standards with superior Marino Grade finishing, it delivers exceptional warmth for workers in extreme cold while maintaining critical flame-resistant properties. It offers the optimal balance between thermal insulation, fire protection, and freedom of movement, making it the preferred choice for protective outerwear in high-risk industries where workers face both cold temperatures and fire hazards.

Each of these specialized thermal quilted fabrics is engineered to address the specific challenges of keeping workers warm, safe, and comfortable in various professional environments, from standard cold workplaces to hazardous conditions requiring multiple safety certifications.Key features: Flame Retardant, Thermal insulation

Certifications: Oeko-tex 100

Flame Retardant Polyester FabricsQ7. Quilted FR-fabric Ovata 2-Sided

Spark + FR-Wadding (Ovata) | Plain 1/1

Q7 Spark 170gsm + 120gsm Ovata + Spark 170gsm

Q7 Spark 170gsm + 150gsm Ovata + Spark 170gsm(0 Certificates)

Flame Retardant fabric

The most comprehensive thermal and safety solution, this quilted fabric features 100% flame-retardant polyester with an additional FR lining to create multiple protective barriers. Certified to EN 11611, EN 531, and EN 470-1 standards with superior Marino Grade finishing, it delivers exceptional warmth for workers in extreme cold while maintaining critical flame-resistant properties. It offers the optimal balance between thermal insulation, fire protection, and freedom of movement, making it the preferred choice for protective outerwear in high-risk industries where workers face both cold temperatures and fire hazards.

Each of these specialized thermal quilted fabrics is engineered to address the specific challenges of keeping workers warm, safe, and comfortable in various professional environments, from standard cold workplaces to hazardous conditions requiring multiple safety certifications.Key features: Flame Retardant, Thermal insulation

Certifications: Oeko-tex 100

We offer high-quality FR fabrics for protective clothing that come with guaranteed quality. These fabrics are essential for industries such as Oil, Gas, Energetics, Heavy Machinery, and Utilities, where compliance with EN 11612 or NFPA 2112 standards is mandatory. XM FireLine™ specializes in designing and manufacturing Flame Retardant fabrics specifically tailored to meet the needs of these industries.

Our FireLine fabrics have undergone rigorous testing, including the Vertical burn test (ISO 15025), and have demonstrated exceptional resistance even after 50 or 100 industrial wash cycles, depending on the specific product line. We ensure the flame retardant properties of our fabrics through the use of high-quality materials and advanced technology.

Our fabrics are made from premium combed cotton, providing them with a combination of softness and durability. We utilize a Double FR-treatment (THPC) technology that guarantees our FR fabrics will not melt or burn even after multiple washes.

Furthermore, our flame retardant fabrics are certified to meet various international standards, including EN ISO 11612, EN ISO 11611, EN 1149, EN 61482, and EN 13034. These certifications demonstrate the reliability and safety of our FR fabrics.

With XM FireLine™, you can be confident in the quality and performance of our FR fabrics, ensuring the protection and safety of workers in high-risk industries.