ESD fabrics for cleanrooms

-

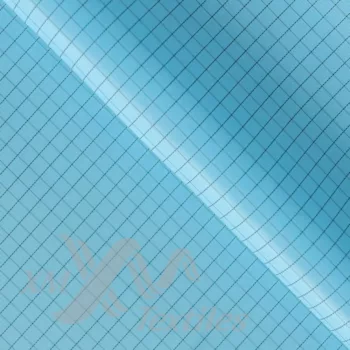

110gsm | 98% Polyester, 2% AS | Plain 1/1

(2 Certificates)

Workwear fabric

CleanStatic-110 is an antistatic fabric made from 98% polyester and 2% antistatic carbon fibre. This antistatic fabric has a plain weave and Belltron antistatic yarn which is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11;" align=”left” ] To prevent electrostatic discharge (ESD) sparks, the antistatic fibres safely dissipate static electricity, eliminating the risk of destroying electronic micro-schemes. CleanStatic-110 is designed for lightweight antistatic garments for CleanRooms.[/show_more]

Key features: Antistatic

Certifications: EN 61340, Oeko-tex 100

ESD fabrics for cleanroomsCLEANSTATIC-110

110gsm | 98% Polyester, 2% AS | Plain 1/1

(2 Certificates)

Workwear fabric

CleanStatic-110 is an antistatic fabric made from 98% polyester and 2% antistatic carbon fibre. This antistatic fabric has a plain weave and Belltron antistatic yarn which is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11;" align=”left” ] To prevent electrostatic discharge (ESD) sparks, the antistatic fibres safely dissipate static electricity, eliminating the risk of destroying electronic micro-schemes. CleanStatic-110 is designed for lightweight antistatic garments for CleanRooms.[/show_more]

Key features: Antistatic

Certifications: EN 61340, Oeko-tex 100

-

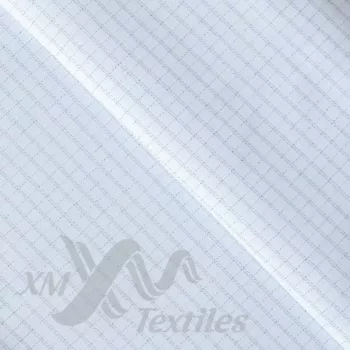

140 gsm | 63% Polyester, 33% Cotton, 4% AS | Twill 2/1

(2 Certificates)

Workwear fabric

CleanStatic-140 is an antistatic fabric. Antistatic fibres safely dissipate static electricity, eliminating the risk of gas explosion and destruction of electronic components. This static dissipative fabric has a twill weave and Belltron static dissipative yarn that is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]A CleanStatic-140 is designed for antistatic garments for cleanrooms (protection of electronic equipment from electrostatic discharge).[/show_more]

Key features: Antistatic

Certifications: Oeko-tex 100, EN 1149

ESD fabrics for cleanroomsCLEANSTATIC-140

140 gsm | 63% Polyester, 33% Cotton, 4% AS | Twill 2/1

(2 Certificates)

Workwear fabric

CleanStatic-140 is an antistatic fabric. Antistatic fibres safely dissipate static electricity, eliminating the risk of gas explosion and destruction of electronic components. This static dissipative fabric has a twill weave and Belltron static dissipative yarn that is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]A CleanStatic-140 is designed for antistatic garments for cleanrooms (protection of electronic equipment from electrostatic discharge).[/show_more]

Key features: Antistatic

Certifications: Oeko-tex 100, EN 1149

-

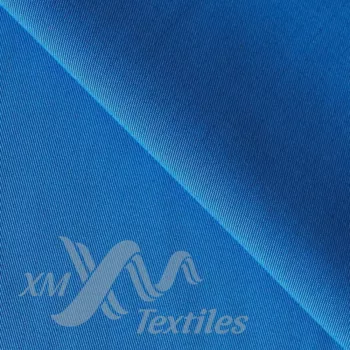

180 gsm | 65% Polyester, 33% Cotton, 2% AS | Twill 2/1

(1 Certificate)

Workwear fabric

CleanStatic-180 TC is an antistatic fabric. Antistatic fibres safely dissipate static electricity, eliminating the risk of gas explosion and destruction of electronic components.This antistatic fabric has a twill weave and Belltron antistatic yarn gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]A CleanStatic-180 is designed for cleanroom antistatic garments. Certified to EN 61340 (Protection of electronic equipment from electrostatic discharge).[/show_more]

Key features: Antistatic

Certifications: EN 1149, EN 61340, Oeko-tex 100

ESD fabrics for cleanroomsCLEANSTATIC-180

180 gsm | 65% Polyester, 33% Cotton, 2% AS | Twill 2/1

(1 Certificate)

Workwear fabric

CleanStatic-180 TC is an antistatic fabric. Antistatic fibres safely dissipate static electricity, eliminating the risk of gas explosion and destruction of electronic components.This antistatic fabric has a twill weave and Belltron antistatic yarn gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]A CleanStatic-180 is designed for cleanroom antistatic garments. Certified to EN 61340 (Protection of electronic equipment from electrostatic discharge).[/show_more]

Key features: Antistatic

Certifications: EN 1149, EN 61340, Oeko-tex 100

-

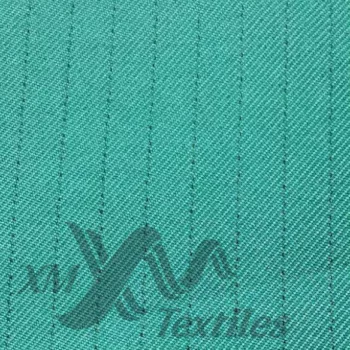

240gsm | 65% Polyester, 33% Cotton, 2% AS | Twill 2/1

(2 Test Reports)

Workwear fabric

CleanStatic-240 TC is an antistatic fabric made of 65% polyester, 33% cotton and 2% antistatic carbon fibre. This antistatic fabric has a twill weave and the addition of Belltron antistatic yarn which is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]To prevent electrostatic discharge (ESD) sparks, the antistatic fibres safely dissipate static electricity. CleanStatic-240 is designed for antistatic garments for CleanRooms.[/show_more]

Key features: Antistatic

Certifications: EN 1149-5, EN 61340-5-1, Oeko-tex 100

ESD fabrics for cleanroomsCLEANSTATIC-240

240gsm | 65% Polyester, 33% Cotton, 2% AS | Twill 2/1

(2 Test Reports)

Workwear fabric

CleanStatic-240 TC is an antistatic fabric made of 65% polyester, 33% cotton and 2% antistatic carbon fibre. This antistatic fabric has a twill weave and the addition of Belltron antistatic yarn which is gridlocked into the surface of the fabric.[show_more more="Show more" less="Show less" color="#629e11" align="left" ]To prevent electrostatic discharge (ESD) sparks, the antistatic fibres safely dissipate static electricity. CleanStatic-240 is designed for antistatic garments for CleanRooms.[/show_more]

Key features: Antistatic

Certifications: EN 1149-5, EN 61340-5-1, Oeko-tex 100

-

New

New150 gsm | Polyester 99%, AS 1% | Twill 2/2

(0 Certificates)

Workwear fabric

Certifications: Oeko-tex 100, EN 13795, EN 1149

ESD fabrics for cleanroomsMinerva-150

150 gsm | Polyester 99%, AS 1% | Twill 2/2

(0 Certificates)

Workwear fabric

Certifications: Oeko-tex 100, EN 13795, EN 1149

-

200gsm | 98% Polyester, 2% AS | Plain 1/1

(0 Test Reports)

Workwear fabric

Oxford-200 AS is our new Antistatic fabric. Antistatic fibres safely discharge static electricity, eliminating the risk of a gas explosion and destroying electronic components. This Antistatic fabric has a plain weave and antistatic yarn in the surface of a fabric.

Key features: Antistatic, Oeko-Tex 10

Certifications: Oeko-tex 100

ESD fabrics for cleanroomsOXFORD-200 AS

200gsm | 98% Polyester, 2% AS | Plain 1/1

(0 Test Reports)

Workwear fabric

Oxford-200 AS is our new Antistatic fabric. Antistatic fibres safely discharge static electricity, eliminating the risk of a gas explosion and destroying electronic components. This Antistatic fabric has a plain weave and antistatic yarn in the surface of a fabric.

Key features: Antistatic, Oeko-Tex 10

Certifications: Oeko-tex 100

ESD clothing made with XM Textiles fabrics is the best solution for protecting electronic components against ESD.

Our CleanStatic fabrics are certified to European Standards EN 1149-3/5 and IEC 61340-5-1. These antistatic fabrics are specifically designed to prevent the ESD effect when working with electronics, high-explosive vapors, or in super-clean lab environments.

ESD occurs when two materials come into contact and then separate, resulting in a spark discharge when a metallic (conductive) object is touched. This discharge can potentially damage electronic circuits, precision machinery, and even cause gas explosions.

To prevent ESD and discharge static electricity in the air, antistatic fibers are woven into the fabric.